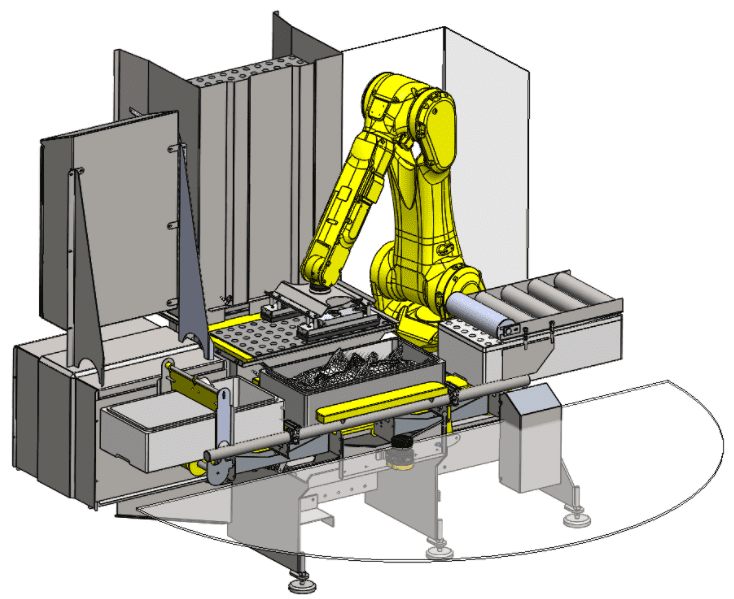

The SR- LID ROBOT is a fully automatic lid positioning on Styrofoam boxes. A lid magazine feeds lids to a pick-up position. The robot places the lid on the box and holds it until a top roller takes over and holds on to it into the strapper. The robot is on one steel foundation and is delivered ready to plug in to power. The safety of the system is secured with a steel fence on the back and a laser safety beam in the front. The boxes come from an ice-dozer into the lid position and are stopped by a box stopper. When the lid is on the box it is released and the conveyor takes it under the rollers and to the strapping machine.

The SR-Lid robot is designed for standard Salmon boxes and has been tested for up to 15 boxes/min.

Optional upgrades

The lid robot is an excellent location for increased quality assurance, as such upgrades can be offered with computer vision and scanning to address the following

- Record image of each box before closing, store with barcode info for lookup due to complaints / claims.

- Verify Ice level in box, mark box for reject / repair on palletizer robot if ice level is insufficient

- Verify lid closing and product placement (fish sticking out, box bulge) and mark box for reject / repair

- Verify product label and barcode and mark for reject / repair.

Key benefits:

- Automatic reliable lid closing system.

- High capacity.

- Plug and play

- quality control of finished product

- Scalable system with automatic lid magazines

- Complete turn-key solution.

Our systems are fully automatic and are operating in several locations around the world.